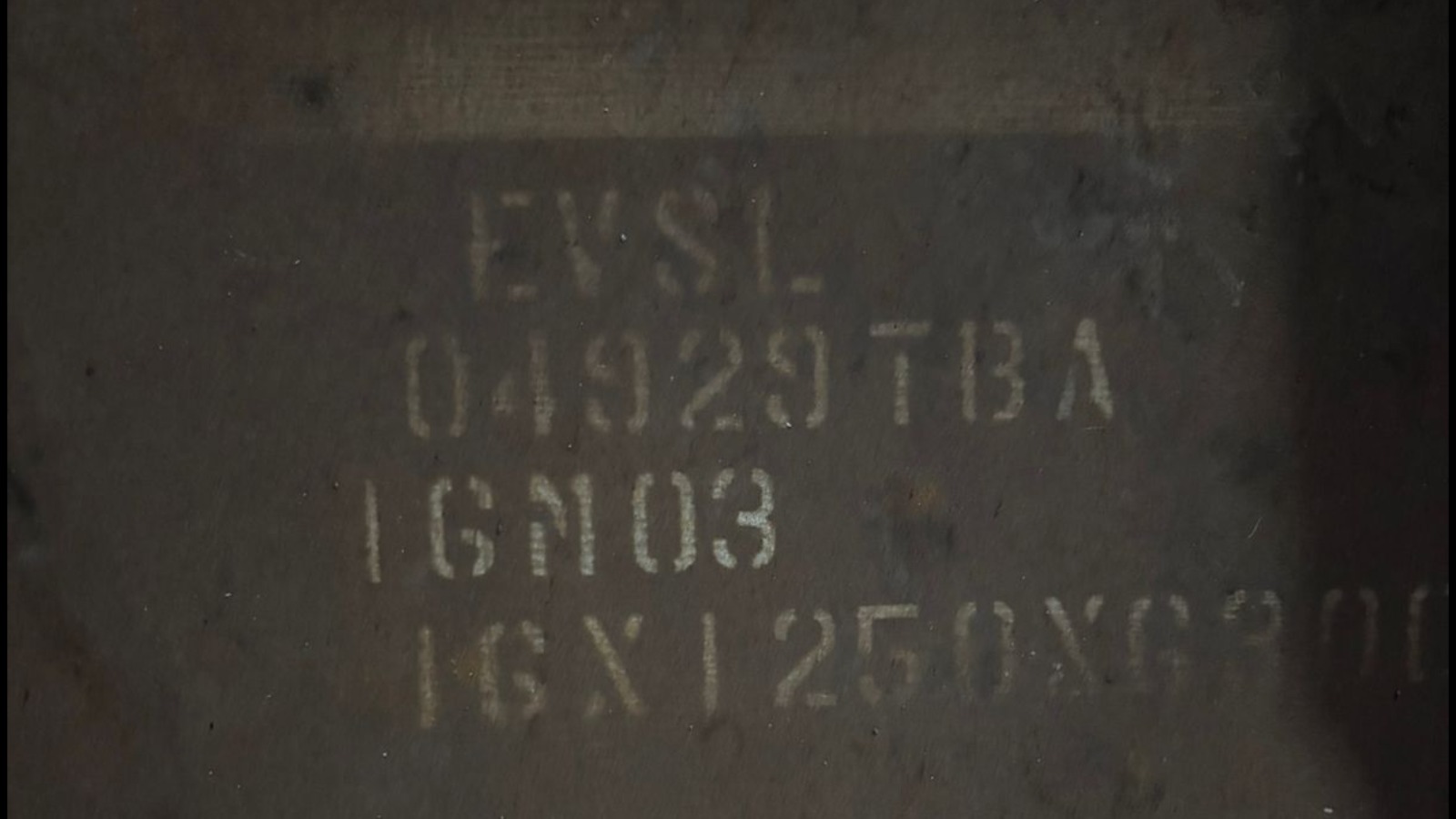

16Mo3 (Molybdenum-Alloyed Pressure Vessel Steel) 16Mo3 is a chromium-molybdenum alloy steel grade specified under EN 10028-2, designed for elevated temperature service in pressure vessels and industrial boilers. With added molybdenum content, 16Mo3 provides excellent heat resistance, improved mechanical strength, and enhanced resistance to oxidation and creep. This grade is widely used in high-temperature applications across thermal, chemical, and oil & gas processing sectors. It offers good weldability and formability, making it a suitable choice for fabricating heat exchangers, superheaters, and piping components operating in extreme environments. Key Features: Excellent performance in high-temperature environments (up to 600°C) Enhanced resistance to thermal stress, oxidation, and creep Good weldability and machinability for fabrication ease Reliable performance in corrosive and pressurized conditions Common Applications: Steam boilers and pressure vessels Superheater coils and reheaters Heat exchangers and economizers High-temperature piping systems and headers

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry