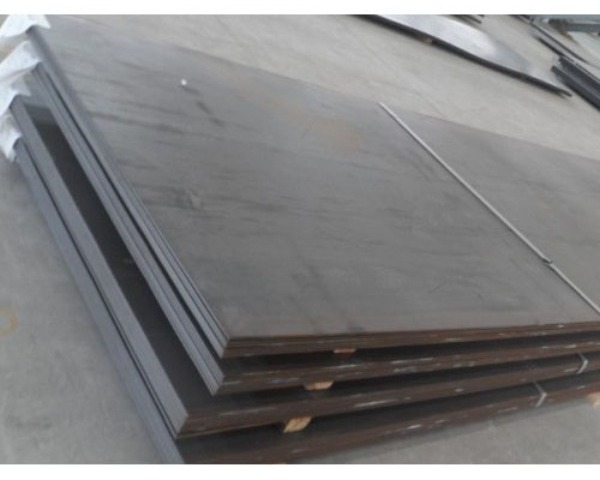

ASTM A36 (Carbon Structural Steel Plate for General Fabrication) ASTM A36 is a widely used carbon steel grade recognized for its versatility, affordability, and ease of fabrication. Designed under the ASTM standard, A36 offers a minimum yield strength of 250 MPa (36 ksi) and is ideal for a wide variety of construction and general manufacturing applications. Its low carbon content ensures excellent weldability and machinability, making it a popular choice for both light and moderate structural work. From structural beams to general-purpose fabrications, A36 delivers dependable mechanical performance and is easy to process using conventional fabrication techniques. Key Features: 250 MPa yield strength suited for light to moderate load-bearing applications Exceptional weldability with no need for special welding procedures High formability and machinability, suitable for shaping and fabrication Cost-effective solution with wide availability and standard sizing Typical Mechanical Properties: Property ASTM A36 Yield Strength ≥ 250 MPa (36 ksi) Tensile Strength 400–550 MPa (58–80 ksi) Elongation ≥ 20% Impact Resistance Moderate Weldability Excellent Common Applications: Building frames, bridges, and civil construction elements Base plates, channels, angles, and standard structural sections Fabricated parts, industrial equipment bases, and machine platforms Storage tanks, supports, frames, and mild-load structures General manufacturing and custom steel fabrication Summary: ASTM A36 remains one of the most widely used carbon steel grades for structural and fabrication needs. Its combination of affordability, workability, and dependable mechanical properties make it a go-to material for engineers and fabricators around the world.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.alloysteelsplate.com/latest-update/astm-a36-carbon-structural-steel-plate-for-genera/99

ASTM A36 (Carbon Structural Steel Plate for Genera...

2025-06-09T04:51:33

ASTM A36 (Carbon Structural Steel Plate for General Fabrication) ASTM A36 is a widely used carbon steel grade recognized for its versatility, affordability, and ease of fabrication. Designed under the ASTM standard, A36 offers a minimum yield strength of 250 MPa (36 ksi) and is ideal for a wide variety of construction and general manufacturing applications. Its low carbon content ensures excellent weldability and machinability, making it a popular choice for both light and moderate structural work. From structural beams to general-purpose fabrications, A36 delivers dependable mechanical performance and is easy to process using conventional fabrication techniques. Key Features: 250 MPa yield strength suited for light to moderate load-bearing applications Exceptional weldability with no need for special welding procedures High formability and machinability, suitable for shaping and fabrication Cost-effective solution with wide availability and standard sizing Typical Mechanical Properties: Property ASTM A36 Yield Strength ≥ 250 MPa (36 ksi) Tensile Strength 400–550 MPa (58–80 ksi) Elongation ≥ 20% Impact Resistance Moderate Weldability Excellent Common Applications: Building frames, bridges, and civil construction elements Base plates, channels, angles, and standard structural sections Fabricated parts, industrial equipment bases, and machine platforms Storage tanks, supports, frames, and mild-load structures General manufacturing and custom steel fabrication Summary: ASTM A36 remains one of the most widely used carbon steel grades for structural and fabrication needs. Its combination of affordability, workability, and dependable mechanical properties make it a go-to material for engineers and fabricators around the world.

2025-06-09T04:51:33

Keywords

- goto material

- affordability workability

- wide availability

- machinability suitable

- structural beams

- popular choice

- machinability making

- wide variety

- fabrication designed

- versatility affordability

- fabrication costeffective solution

- moderate structural work

- carbon steel grades

- general manufacturing applications

- minimum yield strength

Submit Your Enquiry