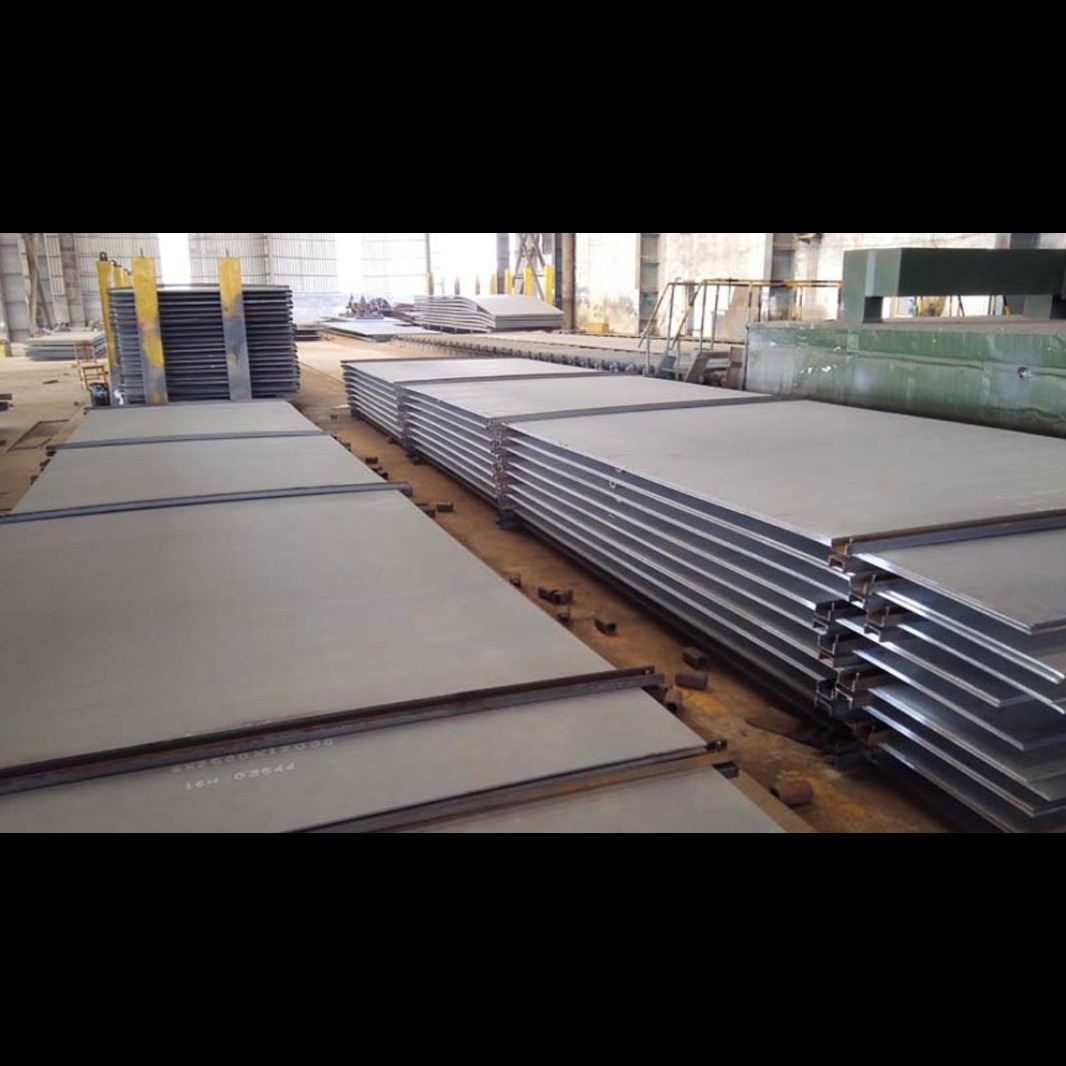

High Manganese Steel Plates – Work-Hardening Steel Built for Impact and Abrasion High Manganese Steel Plates, commonly known as Hadfield Steel, are designed to deliver exceptional impact strength and wear resistance. Containing 11–14% manganese, these plates have a unique property — they become harder when subjected to repeated impact or abrasion. This makes them ideal for high-stress, high-impact industrial environments. Unlike conventional wear plates that degrade over time, manganese steel improves its surface hardness under load while maintaining its core toughness. This self-hardening behavior results in extended service life and reduced downtime, especially in crushing, mining, and rail industries. Key Advantages: Hardens on impact – ideal for aggressive applications Tough, ductile, and crack-resistant under repeated stress Maintains non-magnetic properties even after work-hardening Withstands high levels of shock and gouging Can be welded and fabricated with proper precautions Typical Composition (%): Element Typical Range Manganese (Mn) 11.00 – 14.00 Carbon (C) 1.00 – 1.40 Silicon (Si) ≤ 0.40 Phosphorus (P) ≤ 0.07 Sulfur (S) ≤ 0.03 Iron (Fe) Balance Mechanical Properties: Property Value Range Tensile Strength 800 – 1000 MPa Yield Strength 350 – 500 MPa Elongation ≥ 30% Hardness ~200 BHN (as rolled), work-hardens up to 550 BHN Where It’s Used: Crusher liners, hammers, and impact walls Railway track work, points, and crossings Earthmoving and heavy mining machinery Buckets, chutes, and impact plates in cement plants Shredders, recycling equipment, and heavy-duty wear parts Summary: If your operations demand a material that strengthens under pressure, High Manganese Steel Plates are the ideal solution. With a unique ability to resist wear through work-hardening, they are built to thrive in the harshest environments — reducing replacement frequency and improving long-term efficiency.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.alloysteelsplate.com/latest-update/high-manganese-steel-plates-work-hardening-steel/118

High Manganese Steel Plates – Work-Hardening Steel...

2025-06-25T04:17:45

High Manganese Steel Plates – Work-Hardening Steel Built for Impact and Abrasion High Manganese Steel Plates, commonly known as Hadfield Steel, are designed to deliver exceptional impact strength and wear resistance. Containing 11–14% manganese, these plates have a unique property — they become harder when subjected to repeated impact or abrasion. This makes them ideal for high-stress, high-impact industrial environments. Unlike conventional wear plates that degrade over time, manganese steel improves its surface hardness under load while maintaining its core toughness. This self-hardening behavior results in extended service life and reduced downtime, especially in crushing, mining, and rail industries. Key Advantages: Hardens on impact – ideal for aggressive applications Tough, ductile, and crack-resistant under repeated stress Maintains non-magnetic properties even after work-hardening Withstands high levels of shock and gouging Can be welded and fabricated with proper precautions Typical Composition (%): Element Typical Range Manganese (Mn) 11.00 – 14.00 Carbon (C) 1.00 – 1.40 Silicon (Si) ≤ 0.40 Phosphorus (P) ≤ 0.07 Sulfur (S) ≤ 0.03 Iron (Fe) Balance Mechanical Properties: Property Value Range Tensile Strength 800 – 1000 MPa Yield Strength 350 – 500 MPa Elongation ≥ 30% Hardness ~200 BHN (as rolled), work-hardens up to 550 BHN Where It’s Used: Crusher liners, hammers, and impact walls Railway track work, points, and crossings Earthmoving and heavy mining machinery Buckets, chutes, and impact plates in cement plants Shredders, recycling equipment, and heavy-duty wear parts Summary: If your operations demand a material that strengthens under pressure, High Manganese Steel Plates are the ideal solution. With a unique ability to resist wear through work-hardening, they are built to thrive in the harshest environments — reducing replacement frequency and improving long-term efficiency.

2025-06-25T04:17:45

Submit Your Enquiry